WHAT IS THE ATEX AIR LOCK AND WHERE IS IT USED?

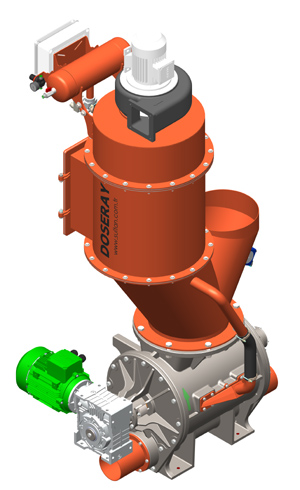

Air lock with its other name is attached, generally used in pneumatic transfer systems (pressure and vacuum) to separate the solid fluid product in the form of powder or granules and the air, fin It is the name given to a mechanical device with a flexible structure. It is widely used especially under filters and cyclones. While diameter and rotation speed determine the capacity of the device, blade tolerances are the most important factor determining the efficiency of the equipment . In addition, air locks can be used as dosers and as proportional unloaders at the bottom of the silo.ex air lock

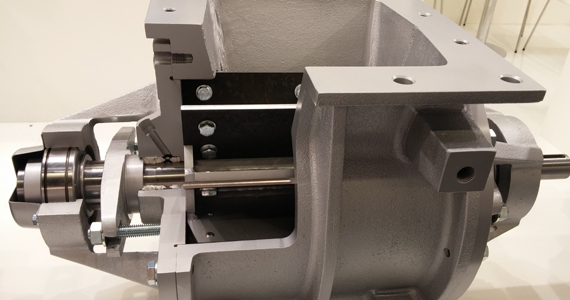

If we briefly define the multiple functions of the capsel, air lock, rotary valve, which is mentioned by many names, it mixes the air with the powder in the form of solid fluid and gravity It can be explained that it separates the product and the compressed air from each other by making use of the force of The Air Lock can show different blade structures, tolerances, rotational speeds depending on the type of process and the product to be used in the process. The Air Lock can also act as a breaker, depending on the nature of the material to be transported. It can work in conjunction with equipment whose main function is shredder. Air Lock - Cell Wheel ST37, Carbon Steel and AISI-304 AISI-316 stainless, Hardox, Ni-Hard. Air Lock bearing types differ according to sealing elements, shaft seal, mechanical seal, seal and process. Air Lock - Cell Wheel; Internal Rotors Bladed, Rounded type, Adjustable blade type, Scraper, Polyamide, can be composed of options such as. As an extra, ATEX version air locks are also included in our production program according to the process needs.

Rotary Valves (

Airlocks) are available with square or round inlet and outlet

flanges. Housing can be fabricated out of

sheet material or cast. Common materials are cast Iron, carbon

steel, 304 SS, 316 SS, and other materials. Rotary

valve , airlock feeders

are often available in standard and heavy

duty models, the difference being the head plate and bearing

configuration. Heavy duty models use an outboard bearing in which

the bearings are moved out away from the head

plate. Housing inlet and discharge configurations are

termed

drop-thru or side entry. Different wear protections are available

such as hard chrome or ceramic plating on the

inner housing surfaces. Grease and air purge fittings

are often

provided to prevent contaminants from entering the packing seals.

Rotary Valve - Airlocks - Star Feeder may be made of ST37 Carbon

Steel and AISI-304 AISI-316 Stainless Steel. Bedding types of the

air locks may be mechanical sealing and felt, again depending on the

hot process.

EDUCTOR FOR ATEX AIR LOCKS

There are some processes that although the air lock is used in

the pneumatic transfer system, the pipe inlet-outlet orientation may

cause you trouble during maintenance. . The removal of pipes during

the said maintenance is not a highly desirable event. In plants like

this, a normal cell wheel can be used instead of a blow thru air

lock (added), and an apparatus that will have a venturi effect is

attached to the bottom. Thus, the lines connected to the system are

not disconnected while maintaining the airlock. This gives you

flexibility in the process.

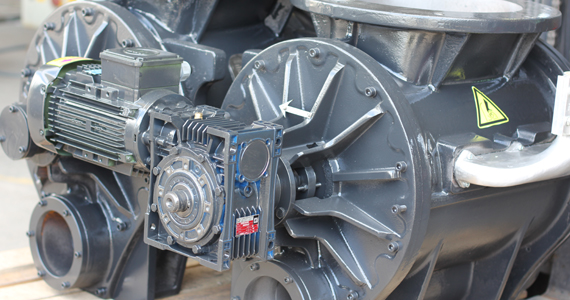

ROTARY VALVE APPLICATION

Rotary Valves (Rotary Feeders)

are widely used in the unloading and dosing of powder and granular

materials in silos, hoppers, pneumatic conveying system, bag

filters, cyclones and other equipment, in a measured and reliable

manner, allowing a detailed volumetric control in transport systems

or processing.

Bulk Solids

Grains

Powder

Fine

powder

Grease (only with special model)

Granules

Application procedures

Discharging

Metering

Feeding

Protective System

Operation

The bulk goods are fed into the

rotary valve rotor via the inlet. This is made up of several

chambers and divides the product flow into small partial flows.

These partial quantities are fed into the downstream process via the

outlet.

Range of application

Chemical

industry

Plastic industry

Pharmaceutical industry

Food industry

Similar industries

FOR atex AIR LOCKS WHAT IS LEAK AIR AND HOW DOES

IT AFFECT THE SYSTEM?

This

subject often causes misunderstandings and misuses. It should be

noted that every airlock must have a rotation tolerance to turn.

This means that there is a gap between the housing and the rotor.

They are generally set to 0.15-.0.30mm in all factory-exit air

locks. If the system will be pneumatically conveyed and the

transported material is somewhat abrasive, this tolerance may

increase over time. Increasing voids can cause problems with air

boiling and bridging upwards from the airlock.

This

subject often causes misunderstandings and misuses. It should be

noted that every airlock must have a rotation tolerance to turn.

This means that there is a gap between the housing and the rotor.

They are generally set to 0.15-.0.30mm in all factory-exit air

locks. If the system will be pneumatically conveyed and the

transported material is somewhat abrasive, this tolerance may

increase over time. Increasing voids can cause problems with air

boiling and bridging upwards from the airlock.

In order to avoid

such situations, especially the leakage air must be directed in blow

throught air locks. they can work under wear. Therefore, the

direction of the leakage air and the direction of the airlock are

important in all pneumatic transfer lines. Otherwise, even with a

very small wear, the system will experience performance problems.

It is important to use blade thicknesses, high alloy steel blades,

caps, rotational speeds, and routing of leaky air for air locks in

processes that are likely to experience wear. it does. That's why

the product selection should be paid attention in the first place.

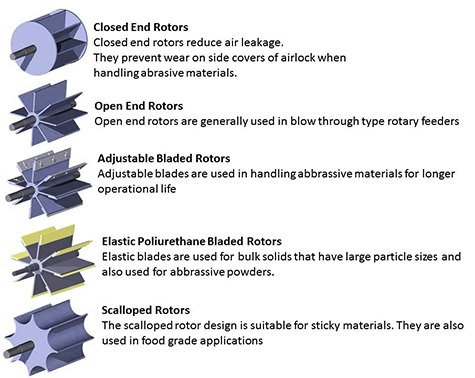

ROTARY VALVE ROTOR TYPES

-

- Rotary Valve - Ailocks-Star Feeder internal

Rotors have options such as blade, rounded type, adjusted blade

type, stripper and polyamide. Discharging

valve for fine and coarse-grained products

Max. capacity through ideal ratio of rotor volume and inlet cross section

Special inlet geometry purpose-built for gentle product handling

With feeding show also suitable for feeding bulk materials into pneumatic conveying systems at up to 1.5 barg (21 psi) -

PDF

brochure

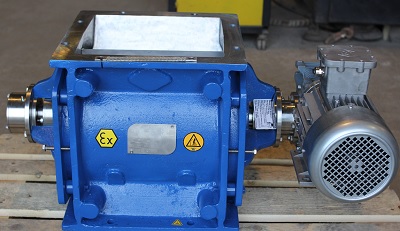

THE ATEX STANDARD FOR ROTARY VALVE

ATEX directives have been drawn up within the European

Union. Each member within the EU should incorporate these

guidelines into their national law. The ATEX directive 114

(2014/34/EU and previously ATEX 95) determines which standards

equipment and products must comply with that are used in

potentially explosive atmospheres. This directive mainly applies

to manufacturers.

ATEX CERTIFICATION FOR AIRLOCK ROTARY VALVE

Gas and dust explosions can cause enormous damage and working with explosive substances and gases therefore entails great risks. From that point of view, it is important to be able to check whether products and installations, work environments and personal competencies meet the set rules and requirements. To confirm ATEX certification is required. Thanks to the implementation of several product improvements, our outboard bearing rotary valves are now also ATEX certified for internal gas zones. This new ATEX certification is the verified proof of DOSERAY ’s high quality standards...

Drop Thru Rotary Valve Models/span>

- 120mm DRAW- cad

- 180mm DRAW-cad

- 200mm DRAW valve -cad

- 220mm DRAW-Cad -cad

- 320mm Draw-cad

- 320mm Long Type Draw -cad

- 350mm Draw-cad

- 450mm Draw-cad

Blow Thru Rotary Valve Models

While pneumatic transport processes differ according to the phases, it may also diffrent in the same phase. Low pressure, that is dilute phase transfer, can be categorized under 2 classes, namely vacuum and pressure. This classification shows, even slightly, differences in the rotary valve - airlocks. Consequently, we perform manufactures according to the air locks to be used on the vacuum and pressure line.

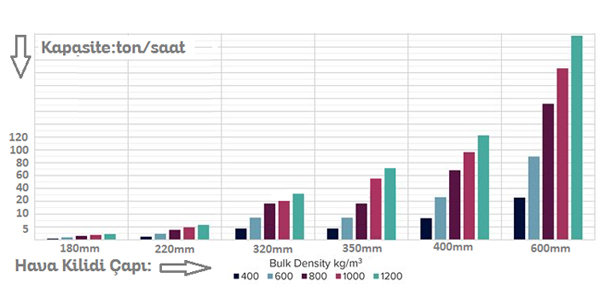

ROTARY VALVE capacıty

Rotary airlock feeders have wide application in industry wherever dry

free-flowing

powders, granules, crystals, or pellets are used.

Typical materials include: cement,

ore, sugar, minerals, grains,

plastics, dust, fly ash, flour, gypsum, lime, coffee,

cereals,

pharmaceuticals, etc...

- Lebels: rotary valve, rotary airlock, airlock valve, rotary feeder, blow through rotary valve, flow through airlock, silo discharge, cyclone discharge, dust collection, pneumatic conveying, rotary air lock valve, rotary valve producer, rotary valve price, rotary valve tecnichal draw